Continuous dry systems

A continuous cooker is an automatic system for cooking and drying slaughterhouse waste. The machine is essentially a horizontal cylinder with a rotating internal stirring shaft. Steam heat circulates in the outer jacket of the cooker, and through a series of tubes that make up the shaft.

The system is controlled by probes that detect the temperature of the product in the initial part and in the final part of the cooker. The temperature can be set between 125 and 140°C, depending on the type of raw materials.

A special level blocks materials from entering the cooker if it is too full. The equipment works automatically if connected to a personal computer, with the following steps: lowering or raising the temperature detected in the first part, raising or lowering the flow of raw materials with the PC, and raising or lowering the variation of the discharge flow in the final part of the system.

The natural humidity in the raw material is extracted as steam and sent to the air heat exchanger, which recondenses and cools the steam to the temperature of 35°C so that it can be sent to the purifier or the incinerator. The dried product that emerges from the cooker is put into a special continuous percolator to begin the first rough separation by gravity of the fat from the solid.

Raw Material Bin

We make various types of raw material bins — each one according to client specifications. These machines are made in carbon steel or stainless steel 304 or 316, with or without covers.

Grinder for carcasses

This machine can grind an entire adult bovine in 20 seconds with a power of 45 kW.

It reduces the material introduced into pieces measuring 50×150 mm.

Crusher

This machine can crush any type of product up to a whole pig or the heads and horns of bovines into small pieces (25×50 mm or under 30 mm.) as required by European standard 1774/2002. We produce these machines with motors from 30 to 110 KW.

Continuous Cooker

A continuous cooker is an automatic system for cooking and drying slaughterhouse waste. The machine is essentially a horizontal cylinder with a rotating internal stirring shaft. Steam heat circulates in the outer jacket of the cooker, and through a series of tubes that make up the shaft.

The system is controlled by probes that detect the temperature of the product in the initial part and in the final part of the cooker. The temperature can be set between 125 and 140°C, depending on the type of raw materials.

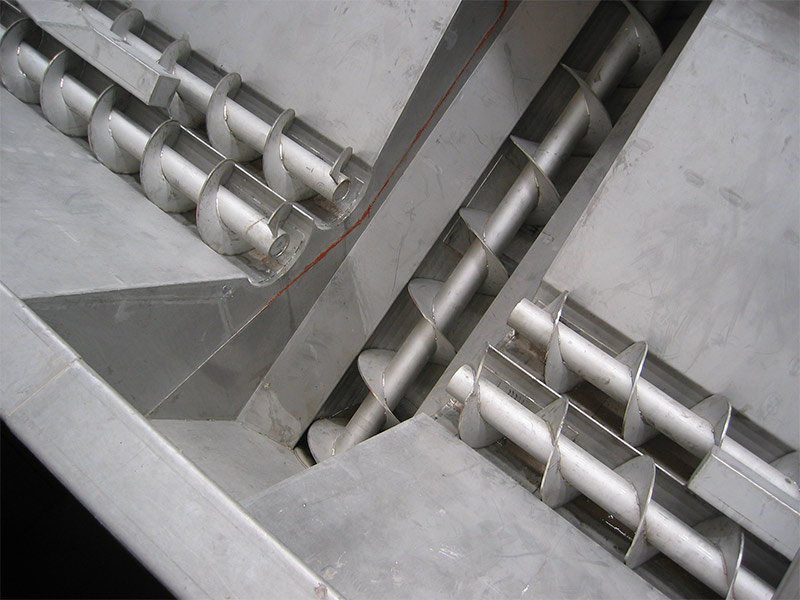

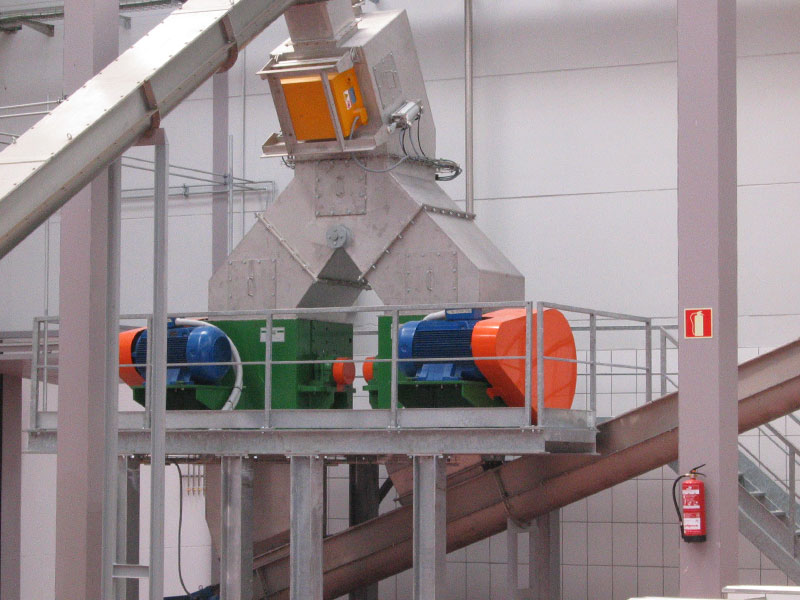

Continuous screw press

It is completely automatic with an electronic pressure and feed regulating system on the panel. We produce components for the machine for each individual product: bone, offal, chicken by-products and hydrolyzed products to reduce the content of fat in the cake to the maximum. Productions from 1,500 to 4.500 Kg/h.

Meal Sterilisation

The processing parameters are: temperature at 133 °, pressure at 3 bar for a time of 20 minutes.

Milling and Bagging

The hammer mill grinds the meal to the desired grain size with grids that can be replaced quickly.

Mills with power from 22 to 132 kW.

The milling line shown is complete with a vibrating filter that separates the meal of the correct grain size to reduce the load on the mill.