Blood systems

Mechanical blood dehydratation

- Continuous system designed to coagulate, mechanically dehydrate in part and subsequently heat dry animal blood

- The initial coagulation and centrifuging phase results in blood with a residual humidity of around 50%. (Example on incoming 1000 kg : 150 kg solid, 150 kg water)

- The residual humidity contained in blood is eliminated in a steam heated drier

- Percentage quantity of blood on animal weight: 3-3.5% (pig = 3-4kg – bovines = 10-15 kg)

- Animal blood meal output: 18-20%

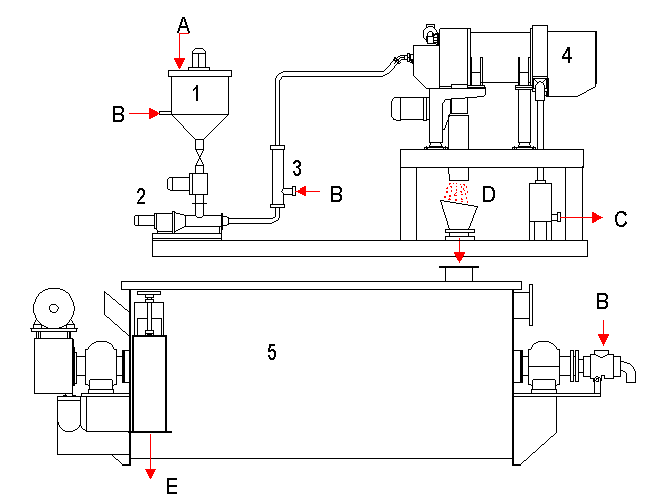

Working diagram of system

Normal production systems

| Type | kg/h incoming | kw absorbed | kg/h steam consumed | kg/h meal produced |

|---|---|---|---|---|

| IS1 | 1000 | 24 | 430 | 150-200 |

| IS2 | 2000 | 30 | 860 | 300-400 |

| IS3 | 3000 | 34 | 1290 | 450-600 |

| IS4 | 4000 | 53 | 1720 | 600-800 |

| IS5 | 5000 | 66 | 2150 | 750-1000 |

Receiving and dosage

Blood arrives from slaughterhouses in a tank that serves as a storage space and feeder for the actual system of machinery. From there, the blood is pumped into the system, passing through a mini-macerator that breaks up any clots and pieces of cartilage.

Pre-heating and coagulation

The blood is pumped into a tank (pos.1) with an agitator, a device that introduces steam directly and regulates the temperature.

From here, a pump (pos.2) sends it to the coagulator (pos.3) and the decanter(pos.4)

Mechanical Dehydration

The decanter is where the solid protein part is separated from the serum.

In this step, 75% of the water originally contained in blood is eliminated mechanically. The solid discharge, made up of about 50% meal and 50% water, passes through a continuous dryer which produces protein meal with a humidity residue lower than 10%.

Drying

The solid discharge, made up of about 50% meal and 50% water, passes through a continuous dryer which produces protein meal with a humidity residue lower than 8%.

Grinding and Bagging

We make various types of raw material bins — each one according to client specifications. These machines are made in carbon steel or stainless steel 304 or 316, with or without covers.

The scales that come out of the dryer are sent to the mill dosing bin. The hammer mill grinds the blood meal to the desired grain size. The tilted screw conveyor carries the meal to the automatic weighing and bagging machine.

Characteristics of the raw material

| Humidity | Fat | Flour | |

|---|---|---|---|

| Blood | 85% | 15% |

Characteristics of finished products

| Farina di sangue | |

| Contenuto in acqua | 8% ca. |

| Contenuto in proteine grezze | 85% ca.0 |

| Digeribilità | 98% |